Theresa Mackay, European Quality Engineer at Ginho Group supports International Women’s Day 2022

With 16 years’ experience across a number of different sectors, Ginho Europe’s Theresa Mackay sees International Women’s Day as an opportunity to champion women in engineering in sectors which decades ago were traditionally dominated by men, but today are providing women around the world with fantastic career opportunities.

Theresa welcomes International Women’s Day theme of #BreakTheBias, and says: “I am really fortunate to work for a progressive, inclusive business now and I really do encourage other women to pursue their dreams with confidence and to be proud of their achievements.”

Theresa started work in food retail. Then when she moved down to Nottingham from her native Glasgow, she worked for a plastics manufacturer and it was here that she quickly became fascinated with production processes, engineering and quality control.

Fast forward 16 years and she is thriving in her role as European quality engineer at the Ginho Europe, having worked in aluminium extrusion and rail freight maintenance along the way.

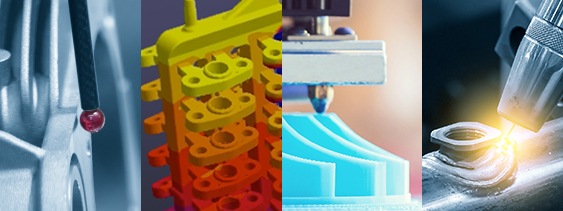

Ginho Europe is developing a global footprint which comprises a world class manufacturing site in China with business centres in the UK, Germany and the USA. From Ginho’s European Centre in Burton upon Trent, over five million high quality precision castings, components and assemblies are exported annually to automotive and other sector manufacturing sites across Europe.

Since joining Ginho Group in 2020, Theresa has been party to many challenges with Covid and Brexit, but the business had a record year in 2021 and has an ambitious growth target for 2022 and beyond.

Part of the senior team, Theresa’s remit is very broad running internal and external audits for customer contracts, research and development, running quality management systems, advising customers, supplier support, data analysis with some health and safety responsibilities too.

“We supply some of the world’s leading automotive brands with divisions in several continents that require consistent, just-in-time support to their local manufacturing sites. This means that quality has to be in everything! It has to run through the business. And as a result, our on-time performance, quality rating and overall customer satisfaction scorecard measures are all over 90%, including 98% for on-time delivery, but we have to be permanently ahead of the game.”

Theresa’s favourite part of the role is getting involved with new products and being part of the planning process. She says: “I love working out how we can make the part and predicting the challenges so they don’t become problems.”

This year, Theresa will be overseeing ISO 9001 for Ginho’s operation in Germany and she is hoping to go to China to visit the company’s state of the art factory, to see the manufacturing process in real life. She says: “I find our Chinese colleagues hugely respectful and helpful – and would love to see production first hand.”

Passionate about engineering and passionate about encouraging more women into the field, Theresa’s advice to any woman thinking about a career in this area is: “Go for it! I did not go down the academic route, but I would recommend it to others.” Theresa has however successfully completed numerous vocational training courses covering health and safety, ISO 9001 auditing and driving a forklift truck!

Theresa adds: “I am very lucky that at Ginho there is a very inclusive culture with a truly equitable environment that allows every member of the team to thrive, regardless of gender. And I can’t wait to see what the future holds and what we can achieve together as a team.”

![]()