Ginho have a world class production facility with world leading technology enabling us to produce a wide range of investment castings, hydroformed tubular components and assemblies.

Ginho has invested in core technology in investment casting, precision tube hydroforming, CNC machining, riveting, and welding.

Continued assessment throughout all company areas enables us to maintain, enhance, and improve processes, operations, logistics, and technology to provide customers with quality products and services. With the companies international facilities covering all primary time zones, Ginho has all of the in-house capabilities to produce and deliver bespoke and high-volume requirements economically 24/7.

Scroll down to find out more.

Investment Castings

Centrifugal Castings

Machined Parts

Tubes & Hydroforming

Operations & Logistics

Ginho understands the importance of operations and logistics to provide just in time delivery solutions to our worldwide customer base. We have strategic facilities in each major time zone to support the 24/7 needs of our customers, with each facility offering technical/quality, distribution/warehousing, sales, and customer service. We have developed strategic supplier agreements with international logistic providers, allowing Ginho the resources to offer a variety of transportation solutions.

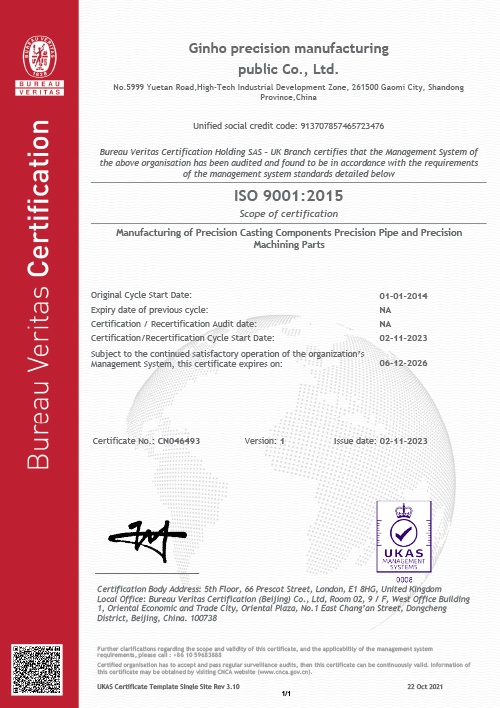

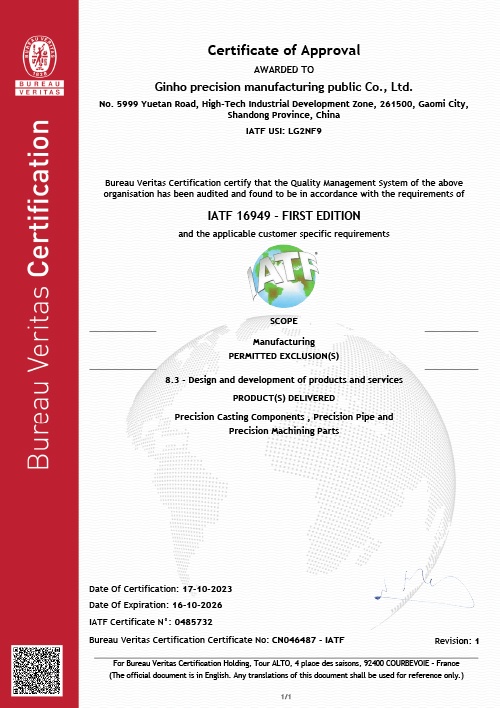

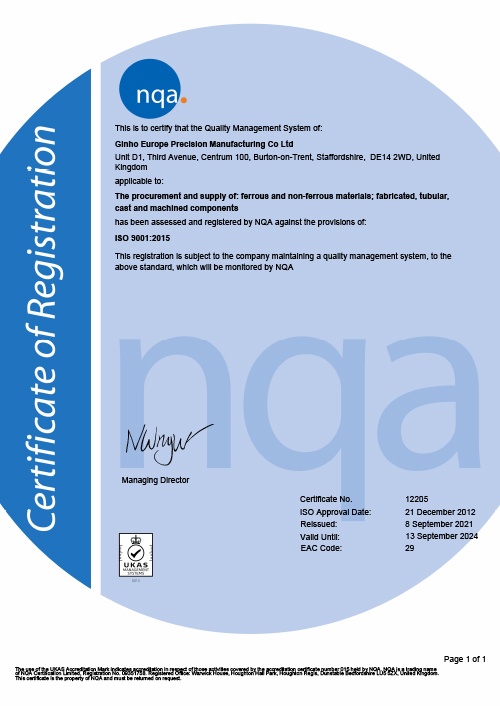

Quality

With our leading technologies and advanced inspection equipment, our quality commitment has enabled Ginho to develop partnerships with many of the world’s most respected manufacturing companies.

Our Quality Certificates

See below list of the Equipment we use to maintain the highest standards of quality and precision.

Spectrometer

Used to verify and control chemical composition of material.

Rockwell / Brinell Hardness Tester

Used to ascertain the hardness value of material.

Tensile Test Machine

Enables us to check the mechanical properties of material in aspects of tensile stress, elongation & yield stress.

2D Projector

Used to measure relative characteristics by projection in a two-dimensional coordinate system

Metallographic Analysis:

Used to make analysis of metallurgical structure of material to ensure it conforms to specification.

Profile Meter

Used for measuring the profile of lines & sections.

Fluorescent Magnetic Particle Detector:

Used to detect surface defects of magnetic metal parts by adopting fluorescent magnetic powder.

Salt Spray Testing Equipment

To test corrosion resistance in an accelerated atmosphere.

Pressure Test

Leak testing of parts under specified conditions.

Chemical & Physical testing lab

Chemical and Physical Testing. Castings produced at Ginho must meet rigorous industry standards. Certifications for material compliance of strength and chemistry are delivered with products provided to our customers.

Vickers, Brinell and Rockwell test equipment

Enables us to test the hardness of the material.

Fully automatic cleanliness detection system

Ginho has a fully automatic cleanliness detection system in place.

X-ray detection machine

This enables us to X-ray the components.

Eddy Current tester

This verifies weld integrity in tubular components.

Visible florescent penetrant inspection

Two types of penetrant visible and fluorescent are used. Visible dye penetrants are usually red and require only ambient light for inspection. Fluorescent dye penetrants are green/yellow and require the use of an ultraviolet light. The fluorescent penetrant method can detect finer discontinuities.

CMM

Ginho has a wide range of CMM equipment at our disposal.

Automatic de burring and Magnetic de burring

This is process can be used in the production process if required to remove burrs on the castings post machining.

Roughness Meter

Roughness meters, also called “surface roughness meters,” are instruments that measure the smoothness (degree of roughness) of the surface of a target.

Materials & Alloys

Austenitic: 304, 316, 316L, 1.4401, 1.4404, 1.4581, 1.4308,

CF-3, CF-8, CF-8M

Ferritic: 430, 439, 1.4509

Martensitic: 17-4PH, 410, 416, 440

others High nickel alloy material, Inconel, Hastelloy, S25, C40 and S45C

We also have the capability to produce customer specific materials