Having brought hundreds of bespoke components to market for customers over the years, the team at Ginho Europe has accumulated vast amounts of experience in delivering new products to multiple sites across Europe on time and in full.

Adding value at every possible touchpoint, the Ginho team provides a dedicated service for customers throughout the launch process, delivering proactive, pre-emptive project management, whether for 50 prototypes or a 2.5 million part annual order.

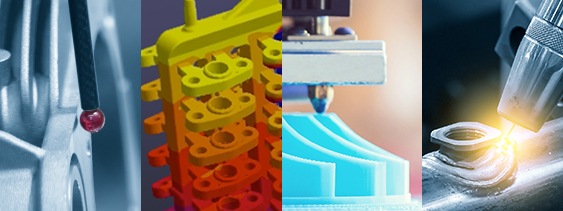

Ginho Europe offers customers a unique service in a number of ways. Many of which emanate from the organisation’s size and scale, as Ginho is essentially a one stop shop with in-house tooling design, testing and manufacturing.

Dedicated service

While Ginho’s manufacturing plant in China is huge and can flex to meet the needs of customers, it is the personal service that offers additional value. Regardless of the massive scale of some contracts, Ginho’s logical approach and digital systems make the entire project comprehensible for all involved.

Key elements of the product launch service include:

- Three-way video calls between the customer, manufacturing plant engineers and product launch team

- A critical path that maps out every stage of the process down to the last hour

- A local, UK-based relationship – with a direct virtual bridge to Asia

- Bi-lingual documentation – which avoids anything being lost in translation between English and Mandarin and vice versa

- Weekly project updates.

Ginho’s Production Part Approval Process (PPAP) systems are granular and while the scope of each and every PPAP requires much scrutiny by definition, as a one stop shop with all stages of production in-house, any extra checks or amendments can be done quickly and efficiently. Examples might be X-ray reports on porosity or adjusting the design of a tool prototype.

Daily check-in

The Ginho Europe team speaks to colleagues at the manufacturing plant every day for an update and with many of them having visited the factory, they are very familiar with the set up over there.

Being in regular contact with customers as a project progresses means that Ginho gets a first-hand view of what is important to that individual, which can regularly result in suggestions being made like changes to packaging or an amended transport schedule that have no additional cost, but improve the overall experience and delivery for the client’s business.

With 15 to 20 different documents for every PPAP, attention to detail is vital. This focus is applied to production too and there is a master schedule with timing for all to see that runs across the 8-to-12-week production process – embracing tooling (which typically takes four weeks); wax models and shell making, shell drying, pouring, shot blasting, rough casting and inspection; machining of the component and inspection; documentation packing and shipping. Each element has an allocation in hours – so any stakeholder can get an accurate view of any product launch programme when they need it.

Communication and being totally transparent is key in the delivery of a successful new product launch and the Ginho team gets a real buzz from seeing how a project progresses and evolves; and customers are benefitting too as they get reassurance at every stage of the process and can update their own stakeholders and colleagues with confidence.

To find out more about Ginho Europe’s product launch service, please email [email protected].